Mold development to mass production

❖ Mold Development Process

- Customer provides sample

- The customer provides a sample for mold development based on their requirements.

- Estimate the mold cost based on the sample and provide a quotation to the customer.

- Customer provides ideas

- Confirm the ideas, appearance, and performance requirements for the product with the customer or the marketing department.

- Evaluate the feasibility of mold development and mass production for the product.

- Estimate the mold cost and provide a quotation to the customer.

Price nego Contract

- Negotiate a price that is acceptable to both parties.

- Sign the contract.

Mold Design

- Use 3D modeling software (CATIA) to create the product model; perform mold flow simulation to predict issues and optimize the design.

- Design the mold's cavity, core, runner, gate, cooling, and ejector systems, and determine the mold structure type.

- Create 2D manufacturing drawings and 3D mold design models, then submit them to the customer for confirmation before entering the manufacturing stage.

Mold Manufacturing

- Select the appropriate mold steel and perform heat treatment according to the requirements to improve hardness and wear resistance.

- Rough machining, precision machining, surface treatment, etc.

- Assemble the mold components into a complete mold.

Quality Inspection

- Inspecting Mold Dimensions to Ensure Compliance with Design

- Testing Mold Functionality and Stability

- Checking for Surface Defects on the Mold

Mold Trial Adjustment

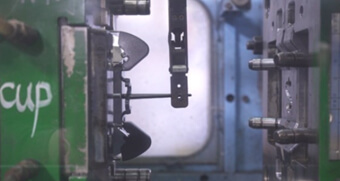

- Install the mold onto the injection molding machine for trial, and check if the injected product has any defects.

- Analyze the trial product and modify the injection parameters or mold structure if necessary.

- Conduct multiple trials and optimize the mold to meet customer requirements.

Mold Acceptance

- Submit samples to the customer for inspection of appearance, dimensions, and functionality.

- Sign the acceptance documents after customer approval.

- ※If the customer confirms it as NG, re-trial and adjustments will be required.

Mass Production Preparation

- After mold acceptance, transfer it to the production department for mass production.

- Perform regular maintenance and upkeep of the mold to extend its service life.

Production Process

- Proceed production trial and verifying compliance with quality standards

- Conduct real-vehicle application testing to ensure stable and reliable installation and performance

Production Preparation

- Correctly set the parameters and production conditions of equipment

- Verify the quality and inventory of raw materials

Mass Production

- Begin mass production and monitor product stability and quality

- Inspect dimensions, appearance, and functionality

Package Delivery

- Package products according to customer requirements

- Select the best Transportation method to ensure on-time delivery

❖ Design Change Process

Design change

- After the mold development is completed or during mass production, the customer requests a design change.

Design analysis

- Analyze the feasibility of the changes that customer requested.

Quotation

- Estimate the modification cost and provide a quotation for the customer's confirmation.

Issue change- order

- If the change is confirmed, issue a design change order.

Mold modification & trial

- Modify the mold based on the design changes.

- After the mold modification is complete, conduct mold trials and sample testing.

Sample confirmation

- Customer signs back the sample if approval.

- According to the standards of confirmed sample to proceed mass production.